1. Icing

Quality assurance of hides and skins begins directly at the suppliers premises. Prior to collection, the hides are cooled down with ice.

Watch movie

Quality assurance of hides and skins begins directly at the suppliers premises. Prior to collection, the hides are cooled down with ice.

Watch movie

Our fleet of trucks collects hides directly from selected suppliers, promptly after slaughtering.

Watch movie

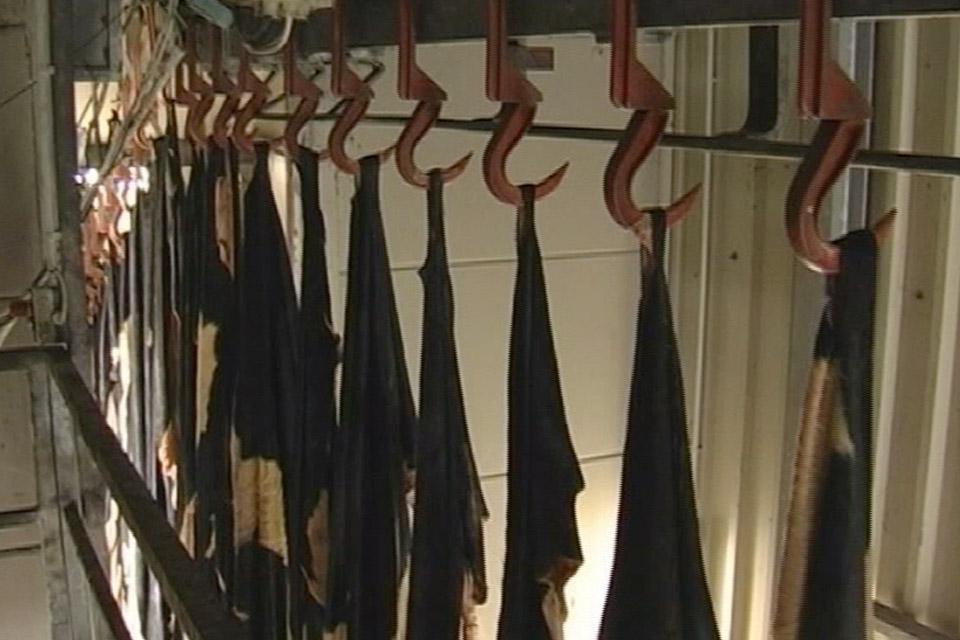

Upon arrival, each hide is hooked and hung on a pipe transportation system.

Watch movie

Non-useable parts of the hides and skins are manually removed.

Watch movie

Each hide is checked in detail and categorized for further processing.

Watch movie

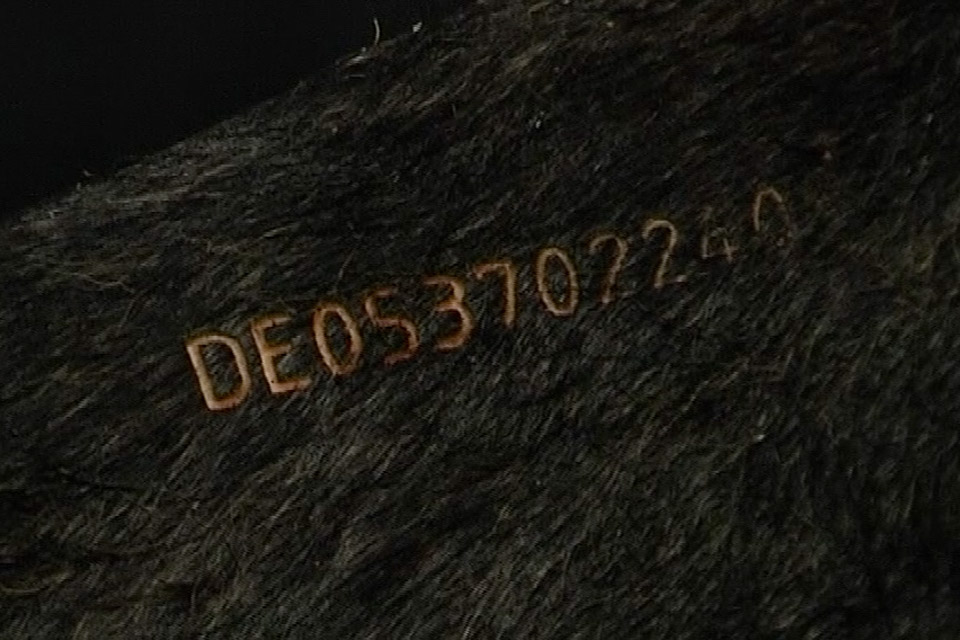

The ear-tage code of the animal is lasered into the hide to enable traceability.

Watch movie

Fresh material for Germany and Europe is stored in our refrigerated warehouses until loading.

Watch movie

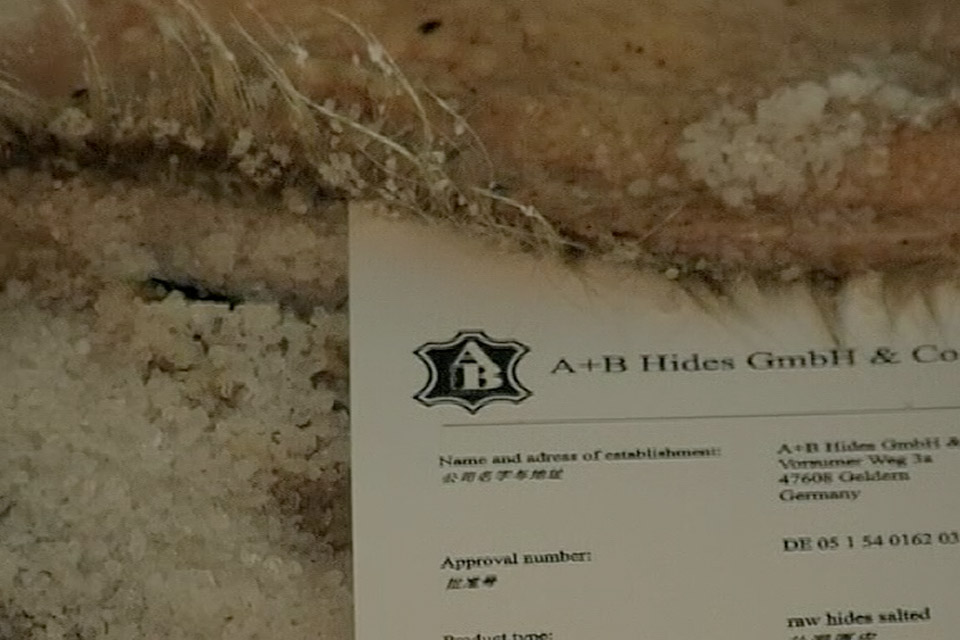

Hides for international clients, for example in Asia, are salted and thus conserved for transport.

Watch movie

Before shipment, salted hides are checked again and palettized.

Watch movie

Until shipment, salted hides are stored in their respective selections.

Watch movie

Salted material is shipped in overseas containers.

Watch movie

Fresh material is delivered to the client with a core temperature of 2°C.

Watch movie